Cangzhou Gerun Carton Machinery Co., Ltd. is a professional company engaged in the

design and manufacture of carton machinery. The company is located

in Cangzhou Dongguang, the northern carton machinery production

base. Over the years, it has always been a leader in research,

development and production.

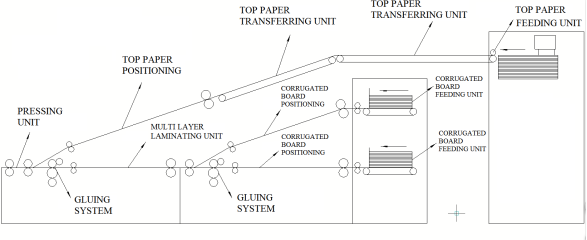

Our Company is a technology-based enterprise mainly engaged in

corrugated box machinery, dominated by corrugated box production

lines and high-speed ink printing machines, integrating investment,

R&D, design, and manufacturing. It has a systematic and

large-scale industrial structure. It has developed into a leader in

packaging machinery with leading technology and excellent

performance.

Our Company has modern mechanical processing equipment and

professional technicians to provide users with a guarantee for the

production of packaging equipment with reasonable design and

qualified quality. In recent years, in order to meet the needs of

foreign markets, we pay more attention to the development and

production of new high-tech products. Due to the continuous

increase of product types and stable quality, we can achieve zero

product inventory and no complaints from users.

On the premise of ensuring product quality and service, our company

pays more attention to corporate reputation, and always adheres to

the principle of "leading technology, creating quality", starting

from the interests of customers. Provide high-quality products and

services for new and old customers, and win the trust of carton

manufacturers!