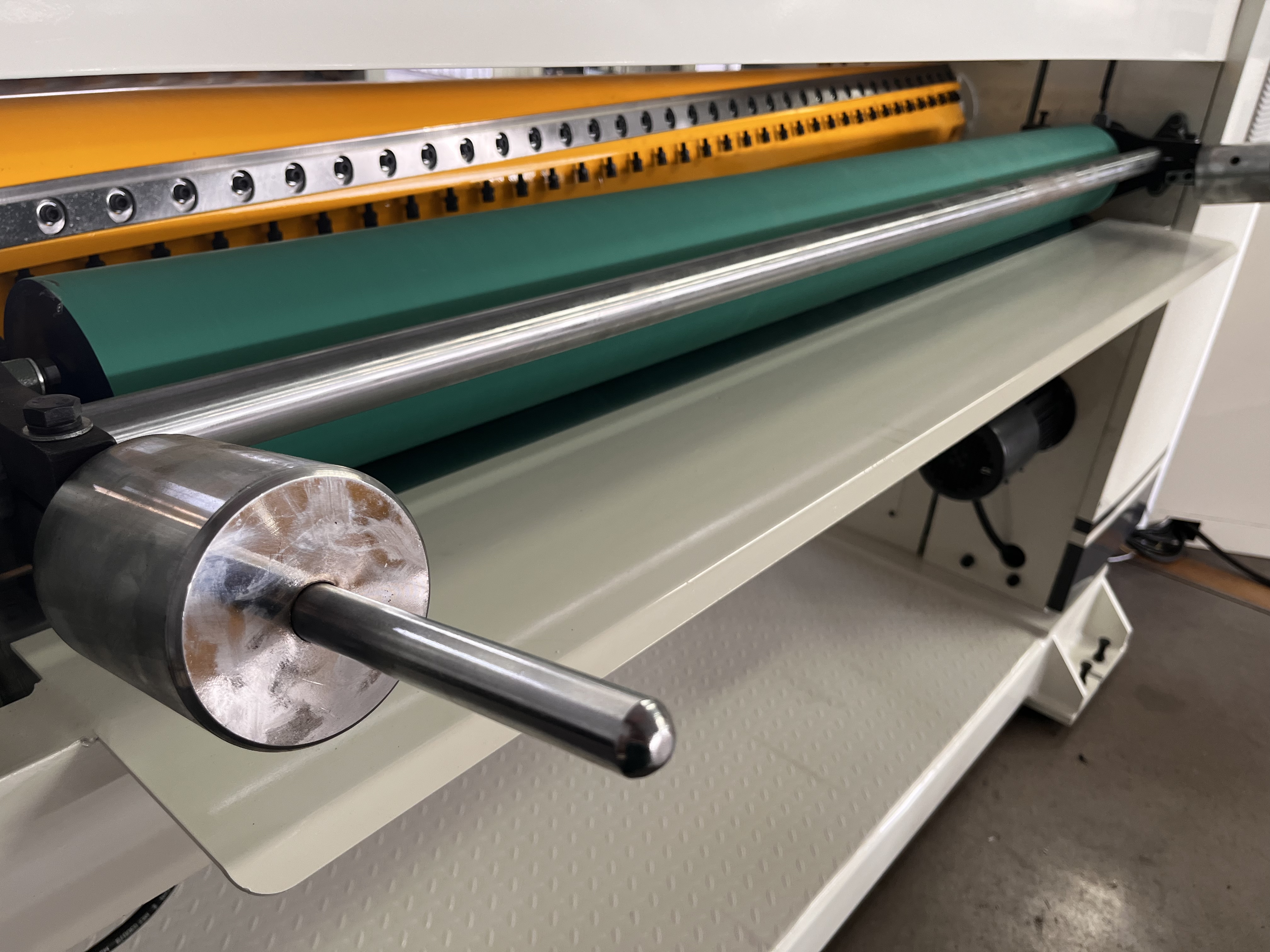

NC-100 NC cutter helical knives

The machine mainly comprises a cutter shaft inner gear (2), a

cutter shaft outer gear (3), a connecting screw (4), a clamping

sleeve (5), a cutter shaft gear (6), a lower blade (7), a lower

blade clamping screw (8), an upper blade top screw (9), an upper

blade clamping screw (10), an upper blade (11), a gear clearance

adjustment shaft (12), a main motor (13), an adjusting rod (14), an

adjusting screw (15), an upper cutter shaft (16), a lower cutter

shaft (17), etc.

1. The upper blade shaft (16) and the lower blade shaft (17) are

made of carbon steel and are heat-treated for good rigidity.

2. When adjusting the blade, insert the blade rod into the blade

rod socket for manual turning.

3. When adjusting the blade, loosen the lower blade clamping screw

(8) by 1/4 turn and adjust the upper blade clamping screw (10) to

make the upper blade (11) and the lower blade (7) fit properly.

4. When adjusting the blade, loosen the gear connecting screw (16)

and adjust the gear side clearance adjustment screw (15) to

eliminate the side clearance of the blade shaft gear.

5. The expansion sleeve (5) connects the blade shaft outer gear (3)

and the blade shaft gear (6) to the blade roller.

6. The spindle motor (13) is the power source for driving the blade

roller.

Installation requirements

1. The machine must be installed on a hard concrete foundation with

a foundation thickness of not less than 250mm;

2. The foundation surface is level and flat with a flatness of not

more than 2mm/m;

3. The machine must be adjusted to a level before being fixed on

the foundation with a levelness of not more than 0.4mm/m; Testing

instrument: square level; Testing position: knife holder fixed

crossbeam.

4. When the machine is installed on the foundation, ensure that the

equipment is parallel with a parallelism of not more than 1mm/m.

Testing instrument: level; Testing position: both sides of the

machine frame at both ends.

Machine installation

When the machine is installed, the user's power supply should be

connected to the machine's power drive cabinet, and an air switch

should be installed at the front end of the air cabinet to turn off

or on the machine's power supply at any time.

When the machine is installed, the user's compressed air pipeline

should be connected to the machine's pneumatic triplet, and a stop

valve should be installed at the front end to turn off or on the

machine's compressed air supply at any time (as shown below).

The air pipe parameters are: PN0.6MPa, DN10.

Adjustment of machine levelness

After the machine is installed, observe the level meter and adjust

the screws until the levelness is within 0.1mm/1000mm×1000mm, then

tighten the nuts of the anchor bolts. Use the same method to adjust

the levelness of at least four corners of the machine.

Structural feature:

- It can store 200 units orders,replace the cutter specifications

quickly and accurately,changing orderswithout stop,And enables

networked computers to facilitate production management.

- Knife shaft drive gears are precision forged steel induction

hardening, backlash-free transmission, advanced keyless connection,

high transmission accuracy.

- Cutting machine adopts inlaid front steel blade knife spiral

structure, serrated knife. scissors, shears, shear force, long

blade life

- Around feed rollers are used the sun gear platen way, smooth

delivery, pressure evenly, easy to crush plate board or cause

blockage

- This model is the braking energy storage (non-dynamic braking), so

the energy consumption in the production process, the average

electricity consumption is 1/3 of an ordinary NC cutting machine,

saving more than 70% power to reach the goal of saving money .

- Precision adjustable no gap gear to ensure precise blade

engagement, running balance.

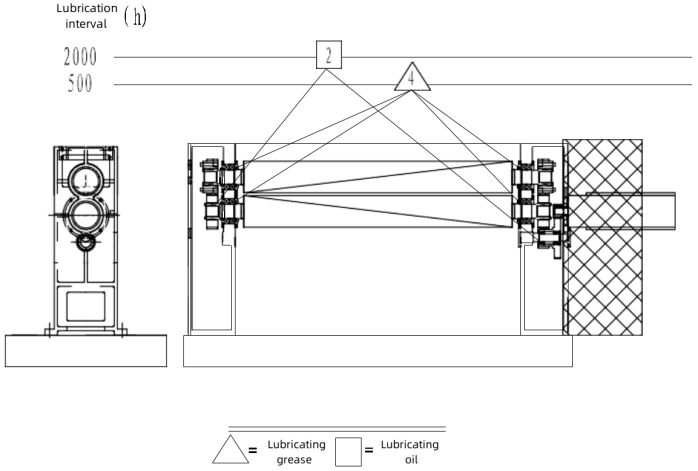

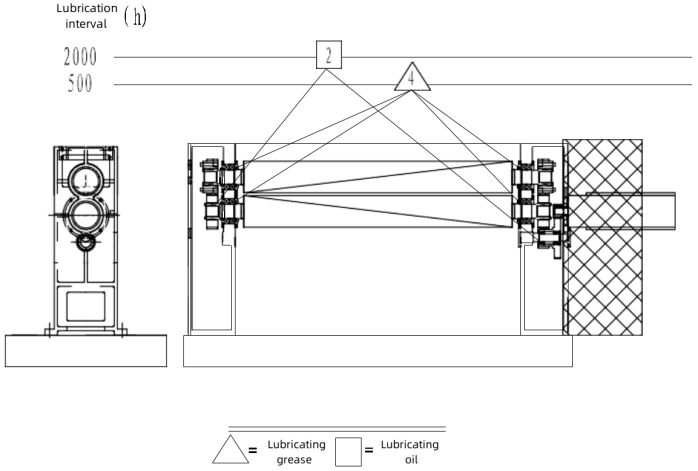

- Using an independent oil pump and filter with two copper

distribution in each gear position oil, lubrication and cooling

- Knife roller: fine quality forged steel material, the balanced,

with good stability.

Roller diameter parameters:

- Cross on the knife shaft center distance:¢216mm

- Before the lower conveying roller diameter ¢156mm

- After the lower conveying roller diameter: ¢156mm

- The front of the platen roller diameter: ¢70mm

- The front of the platen roller diameter: ¢70mm

Note: After all have been grinding rollers, hard chrome plated at

(on except under the knife shaft) dealing

Power motors and electrical parameters:

- main drive motor power:18.5KW Full AC synchronous servo

- Before and after feeding motor power:3KW(Frequency Control)

- Lubricating oil pump motor power:0.25KW

Mainly purchased parts, raw materials and origin:

| Name of main parts | Brands or place of origin | Material and type |

| Full AC servo motor | Shanghai futian | 18.5KW |

| Feeding frequency motor | Hebei hengshui yongshun | |

| bearing | HRB,ZWZ,LYC | Up and down the knife roller bearings from Japan NSK |

| belt | Germany OPTIBELT | |

| Up sleeve | Xianyang chaoyue | |

| Seat belt bearing | Zhejiang wuhuan | |

| Contactors and relays, relays of middle | France Schneider | |

| Proximity Switch | Japan OMRON | |

| Flying shear servo control system | America Emerson | |

| Motion control board | Germany MKS-CT150 | |

| Rotary encoder | Wuxi ruipu | |

| Feeding drive | Taiwan delta | |

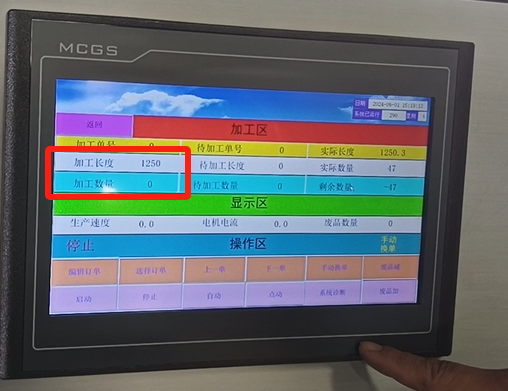

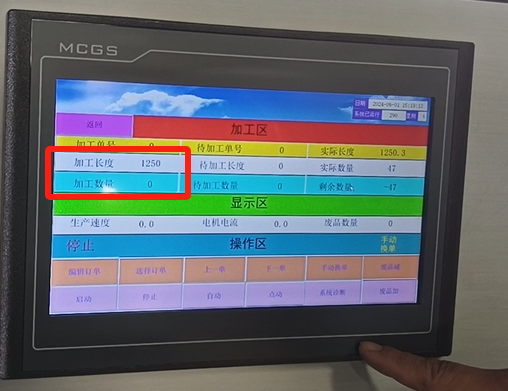

| Human Machine Interface | Taiwan WEINVIEW or MCGS | |

| Sun gear | China shenzhen | |

| Pneumatic components | Zhejiang sonorCSM | |

| Frequency Converter | Siemens | |

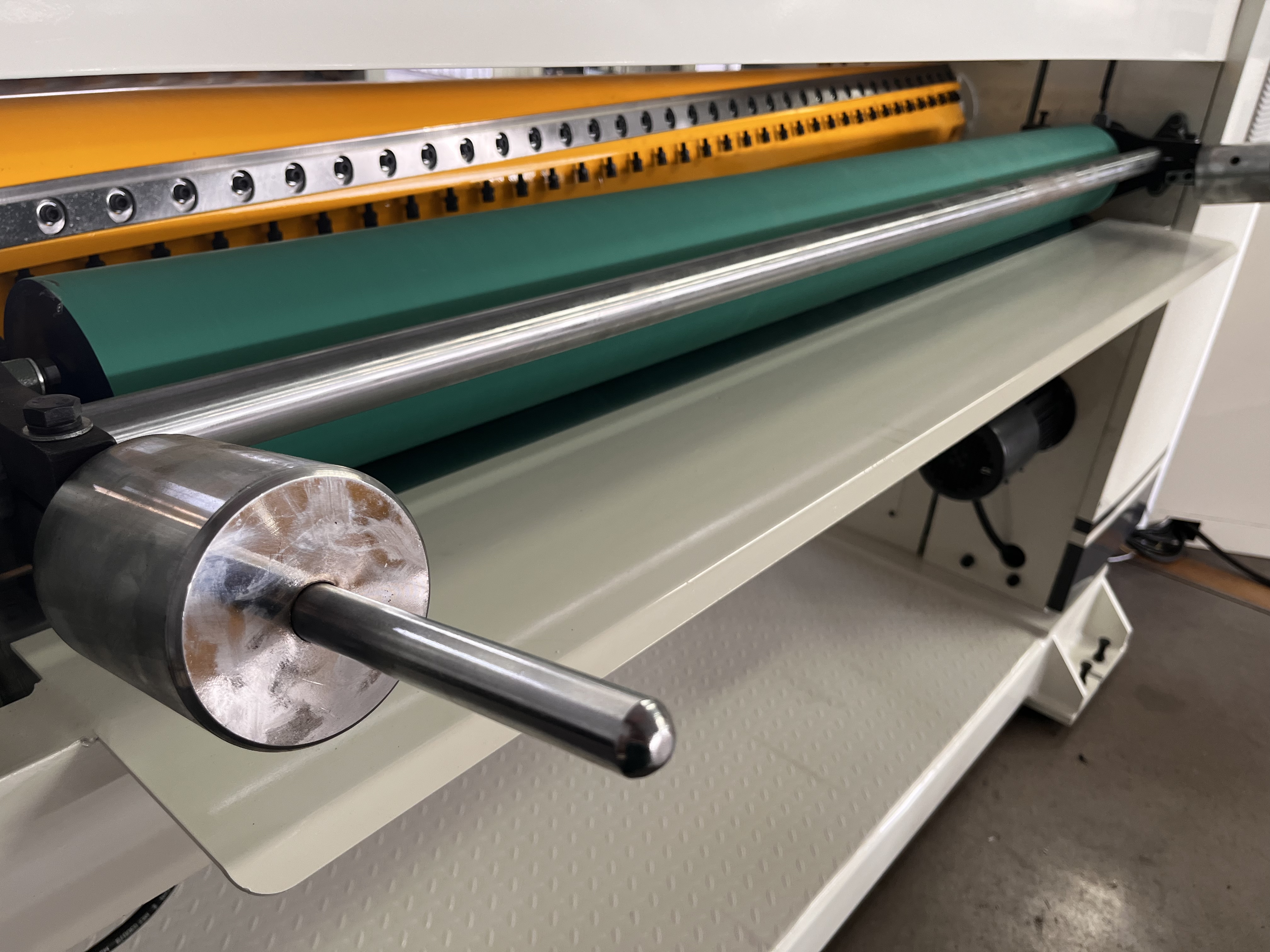

Machine details picture

Operation

操作

① Turn on—启动

② E-STOP—急停

③ Turn off—关机

④ Manual/Automatic—手动/自动

⑤ Speed adjustment—速度调节

Change the operation language:English or 中文(Chinese)

Turn on the main power supply

Click the “Turn on”button

In automatic mode, the machine needs to be connected to a double

facer, and the machine will automatically control the running

speed.

In manual mode, the operating speed is manually adjusted through

the potentiometer. (The operating speed should be slightly higher

than the production line speed)

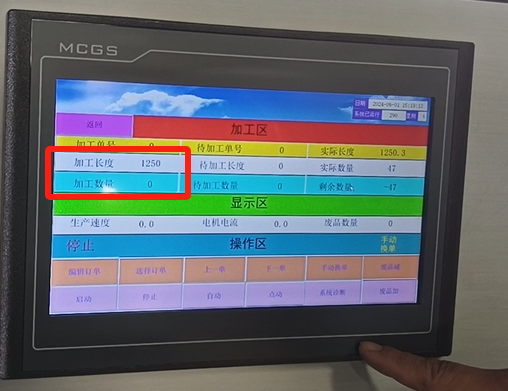

Click the NC cutting control

Setting the “Processing Length”and“Processing Quantity”.

Click the “NC cutting start”,Speed up,The machine will start

working.

Setting the new“Processing Length”and“Processing Quantity”,Will

change the order.

Safety precautions

Safety includes two aspects: first, personnel safety; second,

machine safety.

1. Operators must first receive pre-job skills training.

2. Operators must undergo safety training.

3. Regularly check fasteners, especially those of cross-cutting

blades, to prevent loosening and unnecessary machine damage.

4. Regularly check the working condition of the rotating parts of

the machine, especially the operating condition of the bearings.

5. When replacing and adjusting the cross-cutting blades, please

wear safety gloves to avoid blade injuries.

6. When the machine is working normally, it is strictly forbidden

to enter the machine to avoid casualties and machine damage.

7. Please take good care of the control part software and hardware,

and do not modify or add or subtract them at will.

8. Non-professionals are strictly prohibited from repairing the

machine.

Our company

Product packaging

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer.

Q2: Do you have your own R&D team?

A2: Yes, we can customize products as your requirements.

Q3: How about the quality?

A3: We have the best professional engineer and strict QA and QC

system.

Q4: Can we be your distributor?

A4: We are looking for distributor and agent all over the world.

Q5: How’s the package?

A5: Bubble film,Metal tray and wood packaging

Q6: How’s the delivery time?

A6: It depends on the quantity you need.

Contact us: